-

Phone

86-25-52657506

-

Address

No. 7, Zhongxing East Road, Lishui Development Zone, Nanjing, Jiangsu, China

-

E-mail

LatestProducts

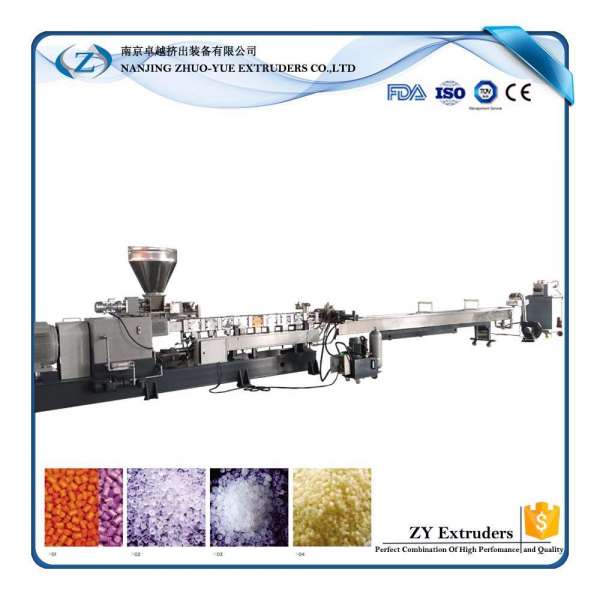

Ce Tse-65 Plastic Granule Raw Material Machine

China Ce Tse-65 Plastic Granule Raw Material Machine, Find details about China Plastic Granule Raw Material Machine, Plastic Extruder from Ce Tse-65 Plastic Granule Raw Material Machine - Nanjing Haisi Extrusion Equipment Co., Ltd.

Description

Basic Info

- Model NO.: TES-65

- Plastic Processed: PP/ PE/Pet/PVC/ABS

- Feeding Mode: One Feed

- Screw: Twin-Screw

- Screw Channel Structure: Deep Screw

- Automation: Automatic

- Color: Optional

- Power: 132kw

- Weight: 4 Tons

- Screw Diam: 62.4mm

- Screw Rotating: 500r/Min

- Trademark: HS

- Specification: CE. ISO 9001

- Type: Pipe Extruder

- Product Type: Granulating Extruder

- Assembly Structure: Separate Type Extruder

- Engagement System: Full Intermeshing

- Exhaust: Exhaust

- Computerized: Computerized

- Ceratificate: Ce. ISO9001

- Voltage: 380V

- Warranty: 1 Year

- Screw Material: W6mo5cr4V2 Material

- Motor: AC

- Transport Package: Packed in Wooden with Soft Plastic

- Origin: Jiangsu. Nanjing

Product Description

Plastic granule raw material machine

1. Characteristics

1. Non woven Fabrics TSE-75DMachine Extruder use innovated design of heater tightened style, it insures high efficiency of heat transfer and high longevity of heater.

2. Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing etc.

3. The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistant and high functions

4. The screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.

5. Non woven Fabrics TSE-75DMachine Extruder adjust to different materials flexible with nlow noise

2. Representative Masterials Mixing nature-changing: PE, PP, PS+SBS, PA+EPDM, PP+NBR, EVA+silicon rubber; PE, PA, PC, CEP+ABS(alloy), PBT+PET, PP+PE Filling nature-changing: PE, PP, EVA, Calcium carbonate, talcum powder, titanic powder; ABS, PC, PS, Aluminum hydroxide, magnesium hydroxide, antimony oxide; PP, PA, ABS+ferrous powder, sulphuric powder, ceramic powder Functional machine pellets: PP, PA, ABS, PBT+anti-burning agent and other auxiliary agents: Combustion-supporting machine pellets; PS+starch: De-composing machine pellets, PE+fog-preventing dipper, stabilizer: Dual-prevention machine pellets; PE, EVA, ABS+carbon black: Black machine pellets Colored machine pellets: PE, PP, ABS, AS, PA, EVA, PET+pigment and auxiliary Intensified glass fibres and carboon fibres: PP, PBT, ABS, AS, PA, PC, POM, PPS, PET+long fires, small fibres, crystals Various cables: HDPE, LDPE, LLDPE, MDPE, EVA, PVC, PP, Lnsulating cables; PE peroxide silicon special materials: EVA heat-melting glue, polyurethane, fluorion rubber Reaction extruding: Polyamide condensate, polyamide melting polymerization, polyethene-adding Exhausting and volatilization: Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene Powder paint: Polyester, ring oxide, lactide, polyurethane, acrylate

1. Characteristics

1. Non woven Fabrics TSE-75DMachine Extruder use innovated design of heater tightened style, it insures high efficiency of heat transfer and high longevity of heater.

2. Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing etc.

3. The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistant and high functions

4. The screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.

5. Non woven Fabrics TSE-75DMachine Extruder adjust to different materials flexible with nlow noise

2. Representative Masterials Mixing nature-changing: PE, PP, PS+SBS, PA+EPDM, PP+NBR, EVA+silicon rubber; PE, PA, PC, CEP+ABS(alloy), PBT+PET, PP+PE Filling nature-changing: PE, PP, EVA, Calcium carbonate, talcum powder, titanic powder; ABS, PC, PS, Aluminum hydroxide, magnesium hydroxide, antimony oxide; PP, PA, ABS+ferrous powder, sulphuric powder, ceramic powder Functional machine pellets: PP, PA, ABS, PBT+anti-burning agent and other auxiliary agents: Combustion-supporting machine pellets; PS+starch: De-composing machine pellets, PE+fog-preventing dipper, stabilizer: Dual-prevention machine pellets; PE, EVA, ABS+carbon black: Black machine pellets Colored machine pellets: PE, PP, ABS, AS, PA, EVA, PET+pigment and auxiliary Intensified glass fibres and carboon fibres: PP, PBT, ABS, AS, PA, PC, POM, PPS, PET+long fires, small fibres, crystals Various cables: HDPE, LDPE, LLDPE, MDPE, EVA, PVC, PP, Lnsulating cables; PE peroxide silicon special materials: EVA heat-melting glue, polyurethane, fluorion rubber Reaction extruding: Polyamide condensate, polyamide melting polymerization, polyethene-adding Exhausting and volatilization: Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene Powder paint: Polyester, ring oxide, lactide, polyurethane, acrylate

|

Mode |

Diameter (mm) |

L/D |

Screw rotary speed (r/min) |

Motor power (kw) |

Torque (N.m) |

Capacity (kg/h) |

|

TSE-20 |

22 |

32-44 |

600 |

5.5 |

43 |

1-10 |

|

TSE-30A |

31 |

32-48 |

500 |

11 |

105 |

5-30 |

|

TSE-30B |

600 |

15 |

119 |

5-40 |

||

|

TSE-40A |

41 |

32-52 |

600 |

15 |

119 |

65-110 |

|

TSE-40B |

400 |

22 |

263 |

90-150 |

||

|

TSE-52B |

51.5 |

32-64 |

600 |

75 |

597 |

225-250 |

|

TSE-65B |

62.4 |

32-64 |

600 |

90 |

716 |

250-300 |

|

TSE-75B |

71 |

32-64 |

600 |

132 |

1050 |

350-550 |

|

TSE-75D |

71 |

32-64 |

600 |

220-250 |

1990 |

500-1000 |

|

TSE-95A |

93 |

32-64 |

500 |

250 |

2387 |

600-1000 |

|

TSE-95B |

93 |

32-64 |

600 |

315 |

2506 |

800-1200 |

|

TSE-135 |

133 |

32-64 |

500 |

750 |

7162 |

1500-2250 |